| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SNAKE |

| Model Number : | 90KW-160KW |

| Certification : | Yes |

| Price : | USD50000-150000 |

| Payment Terms : | T/T |

| Supply Ability : | 1000 set per year |

| Delivery Time : | 5-8 work days |

90KW-160KW Medium Frequency Induction Heating Machine

(1)All-solid-state IGBT inverter functional regulation,soft

switching dual resonant frequency control auo-tracking technology

are high-reliability assurance.

(2)Ultra-smal volume,saving customers 10 times the production

space.

(3)Efficiency,within the framework of full power,high power factor

power efficiency.

(4)Broadb 1-20KHZ frequency automatic tracking adapt to, not at the

scene debugging.

(5)100% full load,24 hours of continuous work.

(6)Constant output voltage/constant output power control features

selected.

(7)Frequency,power,voltage current the whole show.

Technical Parameter:

| Models | DDZP-15 | DDZP-25 | DDZP-35 | DDZP-45 | DDZP-70 | DDZP-90 | DDZP-110 | DDZP-160 |

| Fixed Power Input | 15KW | 25KW | 35KW | 45KW | 70KW | 90KW | 110KW | 160KW |

| Output Voltage | 70-520V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V | 70-550V |

| Input Power Source | Three Phases 380V±20% 50-60HZ | |||||||

| Output Oscillating Frequency | 1KHZ-20KHZ It’s made based on customer’s requirement of parts heat treatment | |||||||

| Duty Cycle | 100% full load,24 hours of continuous work | |||||||

| Weight | 26.5KG | 28KG | 41KG | 50KG | 55KG | 80KG | 85KG | 116 KG |

| Volume(CM) | 29(W)×50(H)×55(L) | 36×60×72 | 43×90×81 | 52×90×85 | ||||

| others | For normal products,it’s made of normal panel,but can make automatice ones with time PCB function.PCB panel function includes:heating time:0.1-99.9 seconds;retain time:0.1-99.9 seconds. | |||||||

Main application:

Medium frequency machines are usually used in the penetration

heating occasions, For example, (1) Rod heating for forging

(2) Melting of almost all kinds of metals (3) Heating of stators or rotors for fitting ( 4) Heating of tube end for extrusion

(5) Heating of moulds (6) Deep quenching of shafts gears ( 7) Tempering or Preheating of weld-joint etc.

Typital applications;

Application Show

Metal smelting

Main Characteristics:

(1)In medium frequency machines,parallel oscillating structure is

used . IGBT module power components our fourth generation inverting

control technologies are applied.

(2)Wide frequency ranges from 1KHZ to 20KHZ, it is easy to match

the machine according to the parts heating desire.

(3)Due to the parallel oscillating structure, it is easy to get the

best matching of the machine to get high heating efficiency full

power output of generator.

(4)Due to the high technologies of our fourth generation inverting

control, soft accurate switching control is realized to assure the

high reliability low repair of the machine

Advantages applications of models with Timer function::

1. Heating power, retaining power, heating time, retaining time can

be preset adjusted, this makes it possible to control the heating

curve heating time.

2. It is suitable to use in the repeated heating or high speed

heating of small parts;

3. By presetting the timer the power of the generator, retaining

can be realized to a certain extent.

Main circuit of the SPZ medium frequency heating machine:

As said above, parallel oscillating structure is applied in our SPZ

medium frequency heating systems. There are two kinds of

combinations usually used now according to the different

applications:

Combination 1: M.F. generator + compensating cap + coil

This is the most popular combination widely used now, for example,

the M.F. forging furnace melting furnace. Machine of this kind is

simple, low cost, high efficiency.

In this combination, the coil is large or long, usually 3 to 10

meters long copper tube is needed to turn the coil. There is 550V

high voltage directly between the coil is not safe. So to ensure

the safety of the operator, the coil must be insulated properly.

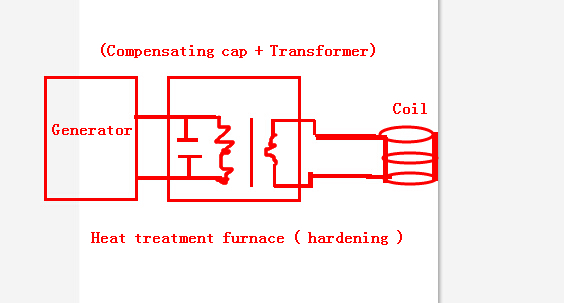

Combination 2:Generator + (compensating cap + transformer)+coil

This combination is also used widely, for example, melting furnace

in vacuum medium frequency quenching.

In this combination, Different output current voltage can achieved

through the changing of the ratio of the transformer to fit

different applications.

In this combination, coil is isolated from the main circuit, so the

coil is safe need low insulation or no insulation.

Due to the adding of the transformer, the size the cost of the

whole heating system are raised, at the same time, transformer

increases the energy consumption. The lower the frequency, the more

the affection is.

The Control theory of the Generator:

Inside the generators, IGBT module our fourth generation inverting

control technology has been used, that is the soft dual control

inverting technology on the basis of parallel oscillating circuit.

In this technology, output power frequency can be controlled

adjusted separately, IGBT module soft switching control technology

are used in the high frequency switching circuit to control the

output power. In the inverting circuit, the IGBT frequency tracing

circuit is applied to achieve high speed accurate soft switching

control. The adoption of new technologies not only improves the

quality reliability of the machine,but also solve the technology

problem on large power induction heating machine makes it possible

to work 100% duty cycle.

Google + Facebook Tweet LinkedIn Pinterest Email Sina

|